Trim toolpath by stock model section

With this feature, is possible use the 3D model rappresentation to detect machined area by previous operations and trim the toolpath , in order to avoid empty area.

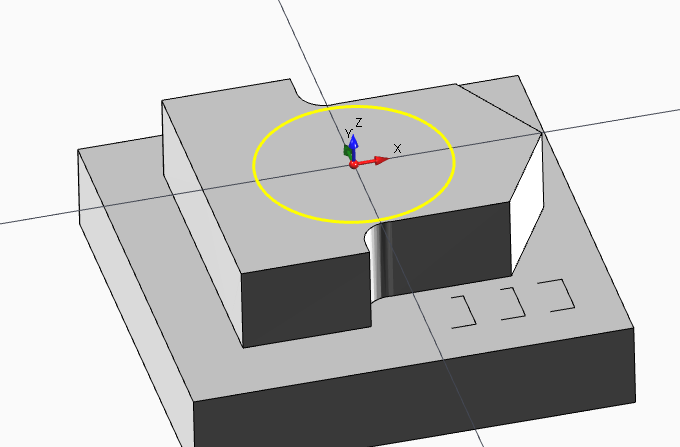

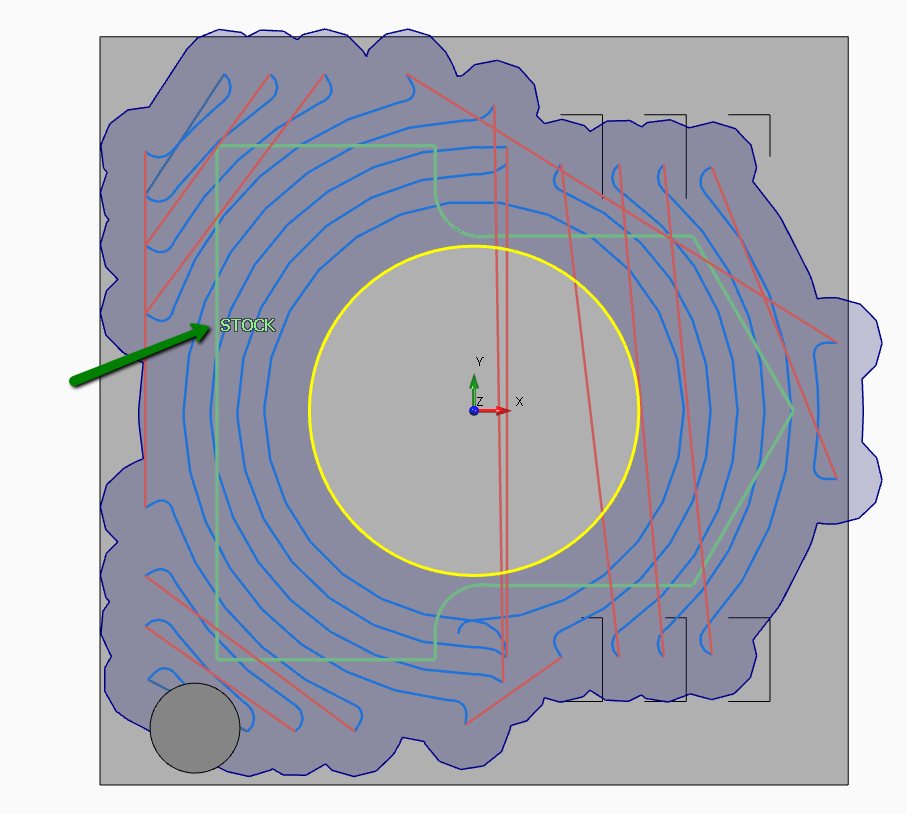

1) For example, let's say this is the current machined stock , after first operation .

2) Now i want to add a second contouring operation , the circle is the geometry for the second operation.

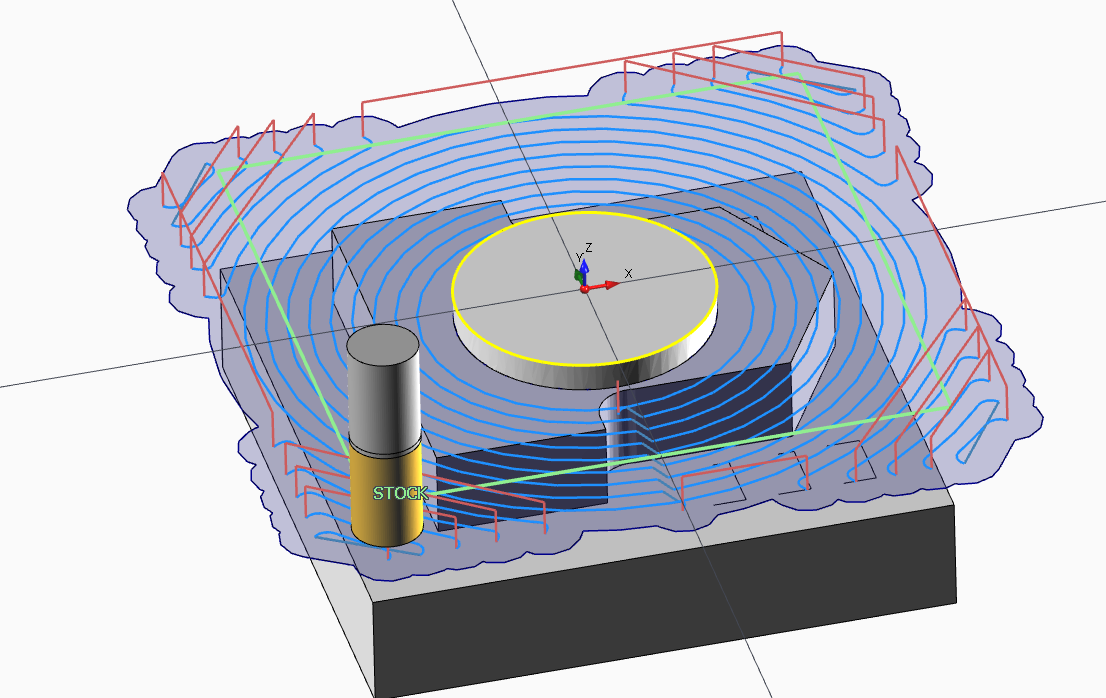

3) This is default toolpath you are going to obtain.

You can observe the toolpath is not optimal , the tool is working on a empty area.

4) To solve you have 2 option :

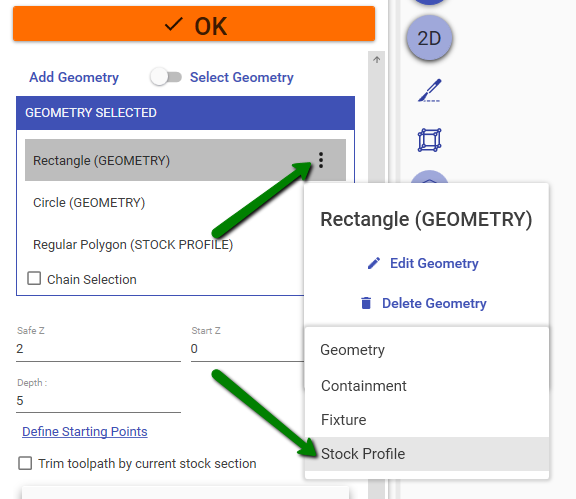

option a) For simple case , you can reselect the geometry used in first operation and setting it as stock .

See images. Set ON this icon to show all hided geometries.

Select the geometries and set them as [STOCK PROFILE] .

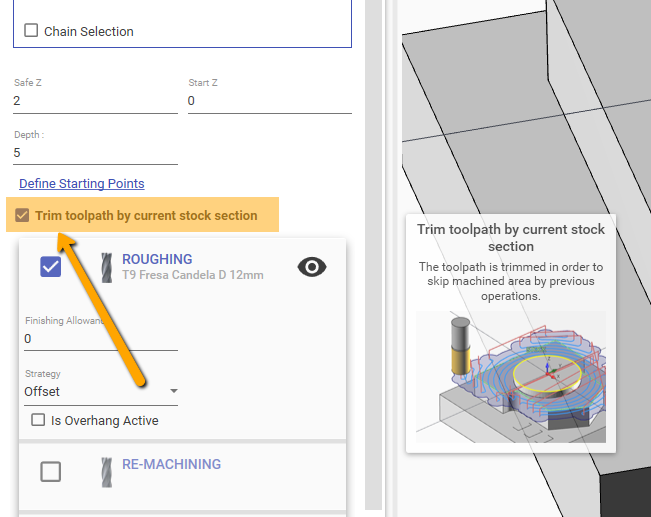

option b) Click on [Trim toolpath by current stock section] .

A planar section of the stock model will be created , and the profiles generated from this section they will be used as stock profile.

This option is more easy to use but it's more computationally expensive.

5) Final result

As final result , you can see the toolpath is trimmed , skipping all useless movement in the already machined area.