Turning Operations

External Turning

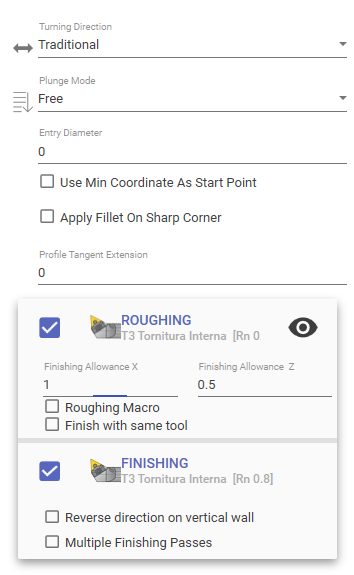

General Properties

Turning Direction - Traditional : The passes direction are Z+ Z- direction.

Turning Direction - Reverse : The passes direction are Z- Z+ direction.

Plunge Mode - Free : Toolpath doesn't consider the tool max plunge angle, it just follow the profile geometry

Plunge Mode - By Tool Geometry : Toolpath engine adjust the profile geometry with the tool max plunge angle.

Plunge Mode - Don't Plunge : Toolpath engine prevent any pocket in turning toolpath

Apply Fillet on sharp corner : Where applicable , a fillet is created between two consecutives segment on the profile, in order to remove the sharp corner.

Profile Tangent Extension : If a value is specified, at start and at end profile, a tangent segment is created.

Use Max Coordinate as start point : If enabled, the toolpath start from the max x coordinate of geometry.

Roughing Properties

Finishing Allowance X - Z : The profile is offsetted in order to leave some material to finishing operation. The offset can be different from x to z direction

Roughing Macro : In the output g-code a macro ( usually G71) will be created.

Finish with same tool : The finishing allowance material is removed by the roughing tool.

Finishing Properties

Reverse direction on vertical wall : machining direction is inverted of vertical wall for better finishing surface.

Multiple finishing passes : Insert a value greater than one to get multiple finishing passes.

Internal Turning

Common properties with external turning are already explained in the section above.

Here the internal turning only properties.

Entry Diameter : Ovveride the start diameter cycle

Use Min Coordinate as start point : If enabled, the toolpath start from the min x coordinate of geometry.