Script Editing - Tutorial 3 - Wrench slot

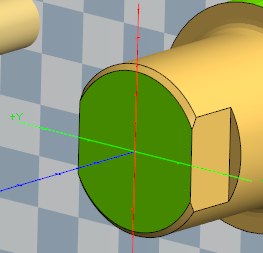

In this tutorial we are going to build a script to create a recurrent machining , the wrench key slot ( i don't know the exact name ) .

It's used to position the wrench tool and screw the component into other assembly.

Summary steps :

- Draw the 2 segment as drive curves . It's important consider line direction correctly, since the side milling machining works on right side by default.

- Draw the outer circle , this is going to be used to trim the toolpath . To do so is enough link it as GeometryMode.StockProfile.

- Create the machining work, SIDE MILLING type.

- Link the 2 segments with the newly created machining work.

- Link the outer circle. In this case link the circle as GeometryMode.StockProfile.

- Create the roughing operation.

- Search the tool . If the outer diameter less than 30mm, search for a 10mm endmill, otherwise if the outer diameter is bigger or equal to 30mm, search a 20mm endmill.

Here the final script :

/// <summary>

/// Create Wrench slot with side milling machining

/// </summary>

public void CreateWrenchKeySlot(double key = 17, double diameter = 20)

{

var halfDiameter = diameter / 2;

var halfDistance = key / 2;

//

// CREATE GEOMETRY - THE DIRECTION IS IMPORTANT , SINCE THE SIDE MILLING WORKS ON RIGHT SIDE BY DEFAULT

var line1 = new Line(halfDiameter, halfDistance, 0, -halfDiameter, halfDistance, 0);

var line2 = new Line(-halfDiameter, -halfDistance, 0, halfDiameter, -halfDistance, 0);

var outerCircle = new Circle(0, 0, 0, diameter / 2);

//

// CREATE WORKS AND SUB OPERATION

var millingWork = AddMachineWork(WorkType.Mill_SideMilling);

millingWork.MillingParams.MaterialToRemove = halfDiameter - halfDistance;

//

// ASSOCIATE GENERATED GEOMETRY WITH MACHINE WORKS

LinkGeometryToWork(millingWork, line1);

LinkGeometryToWork(millingWork, line2);

// I linked the outer circle as STOCK PROFILE to trim toolpath

LinkGeometryToWork(millingWork, outerCircle, GeometryMode.StockProfile);

//

// CREATE SUB-OPERATION

var roughingSubOp = millingWork.AddSubOperation(SubOperationType.Roughing);

//FOR BIGGER CIRCLE DIAMETER I CHOOSE A BIGGER TOOL

var endMillDiameter = 10.0d;

if (Unit == MeasureUnit.Metric)

{

if (diameter >= 30)

endMillDiameter = 20;

}

else

{

if (diameter >= 1.2)

endMillDiameter = 0.8;

}

roughingSubOp.Tool = FindRotaryTool(ToolType.MillType_EndMill, endMillDiameter);

}