Script Editing - Tutorial 5 - Hole Recognition

This tutorial is an example on how you can speed up the program creation from existing 2D geometry with different machined holes.

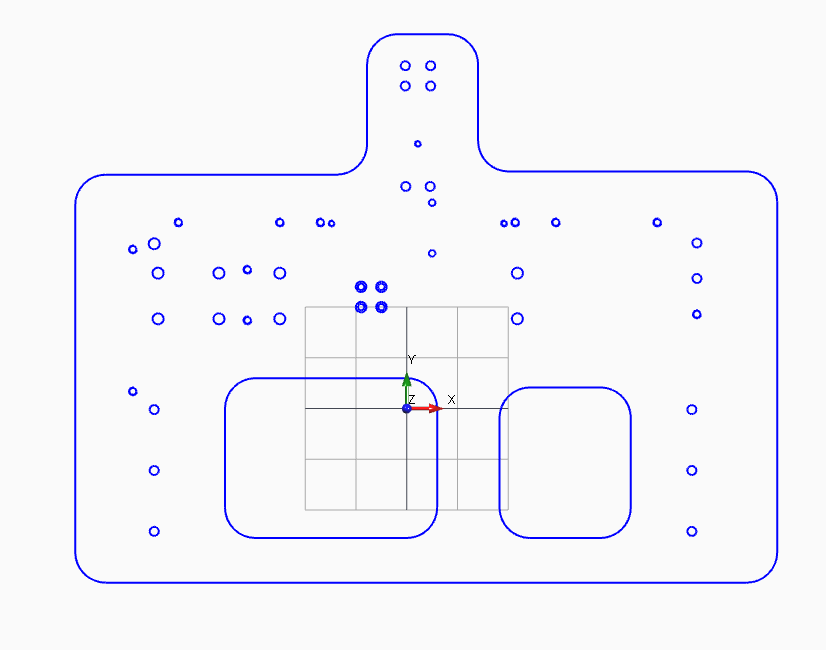

Sample part :

In this sample part you can see different taped holes, counterbore and simple hole. We can recognize and classificate some of these diameter and associate related machining strategies.

For example , a inner circle of diameter 5mm , with an concentric arc of diameter 6mm, it represents a M6x1 tapped hole.

Or a 6.5mm inner diameter with a 10.5 outer circle, most probably it's a counterbore hole.

This time the script is composed by several functions , the necessary step are :

- Recognize a certain feature ( tapped hole, counterbore , etc )

- Associate a machining strategy to extracted recognized geometry

- Process the machining strategy.

Holes Recognition script file

Now we create a new script file and call it "HolesRecognition".

#load "CommonFunctions.csx"

/// <summary>

/// This is the function you need to call from command line.

/// All the necessary sub-step are called here

/// </summary>

public void HoleRecognitionMain()

{

//Recognize and associate strategies to geometries holes

DefineHolesStrategies();

//It run all the created strategy with method above

RunStrategies();

}

/// <summary>

/// With this function, we recognize geometries as tapped holes

/// or counterbored holes or just a simple drilled holes,

/// and we associate extracted geometries to a machining strategy

/// </summary>

public void DefineHolesStrategies()

{

//

// METRIC -

if (Unit == MeasureUnit.Metric)

{

//TAPPED HOLES - (mm)

AddStrategy(Extract2Diameter(5, 4.2, true), "TapStrategy");

AddStrategy(Extract2Diameter(6, 5, true), "TapStrategy");

AddStrategy(Extract2Diameter(8, 6.8, true), "TapStrategy");

AddStrategy(Extract2Diameter(10, 8.5, true), "TapStrategy");

AddStrategy(Extract2Diameter(12, 10.2, true), "TapStrategy");

AddStrategy(Extract2Diameter(14, 12, true), "TapStrategy");

AddStrategy(Extract2Diameter(16, 14, true), "TapStrategy");

AddStrategy(Extract2Diameter(18, 15.5, true), "TapStrategy");

AddStrategy(Extract2Diameter(20, 17.5, true), "TapStrategy");

//Add here more case

//COUNTERBORED HOLES - (mm)

AddStrategy(Extract2Diameter(6.5, 10.5, false), "CounterboreStrategy");

AddStrategy(Extract2Diameter(10.5, 17, false), "CounterboreStrategy");

//SIMPLE HOLE - (mm)

AddStrategy(ExtractRangeDiameterValues(5, 22), "SimpleDrillStrategy");

}

//

// IMPERIAL

else if (Unit == MeasureUnit.Imperial)

{

// Add data in similar way as above but the dimension expressed in inch

}

}

/// <summary>

/// This strategy is called to create a TAPPED holes

/// machining from recognized geometries

/// </summary>

public void TapStrategy()

{

// These is extracted geometry or selected geometries in viewport

var geometries = GetSelectedGeometries();

// I get thread data compatible with current geometry selection

var threadData = GetThreadDataFromGeometry(geometries.FirstOrDefault());

if (threadData == null) return;// No compatible thread data is found, exit from function.

var tapDia = threadData.DiaMax;

var predrillDia = threadData.PreDrillDia;

var pitch = threadData.Pitch;

var work = AddMachineWork(WorkType.Mill_Drilling);

//Initialize machining work parameters

work = InitWithCustomParameters(work);

//Link geometry to work

LinkGeometryToWork(work, geometries);

//Define parameters

work.MillingParams.ThreadDescription = threadData.Description;

work.MillingParams.ThreadPitch = pitch;

work.MillingParams.DrillHoleDiameter = predrillDia;

work.MillingParams.DepthDrill = tapDia * 3.5;

work.MillingParams.DepthThread = tapDia * 2.5;

//Create sub operation

var centerDrillOp = work.AddSubOperation(SubOperationType.CenterDrilling);

var drillOp = work.AddSubOperation(SubOperationType.Drilling);

var tapOp = work.AddSubOperation(SubOperationType.Tapping);

}

/// <summary>

/// This strategy is called to create a COUNTERBORED holes

/// machining from recognized geometries.

/// </summary>

public void CounterboreStrategy()

{

// These is extracted geometry or selected geometries in viewport

var geometries = GetSelectedGeometries();

// The geometries should be list of a couples of circles, rappresenting

// the outer and the inner diameter of the counterbore machining.

var firstCoupleOfDiameter = geometries.FirstOrDefault();

if (firstCoupleOfDiameter.Count() != 2)

return;

//By convention the first circle is the bigger.

var circleMax = firstCoupleOfDiameter.OfType<Circle>().OrderBy(c => c.Radius).First();

var circleMin = firstCoupleOfDiameter.OfType<Circle>().OrderByDescending(c => c.Radius).First();

var work = AddMachineWork(WorkType.Mill_Drilling);

//Initialize machining work parameters

work = InitWithCustomParameters(work);

//Link geometry to work

LinkGeometryToWork(work, geometries);

var innerDia = circleMin.Radius * 2;

var outerDia = circleMax.Radius * 2;

//Define parameters

work.MillingParams.DrillHoleDiameter = innerDia;

work.MillingParams.DepthDrill = innerDia * 5;

work.MillingParams.DepthCounterbore = outerDia;

//Create sub operation

var centerDrillOp = work.AddSubOperation(SubOperationType.CenterDrilling);

var drillOp = work.AddSubOperation(SubOperationType.Drilling);

//

// If the counterbore diameter is big, i use a roughing cycle with endmill

if (Unit == MeasureUnit.Metric && outerDia > 16)

{

var endMillCounterboreOp = work.AddSubOperation(SubOperationType.Roughing);

endMillCounterboreOp.Tool = FindRotaryTool(ToolType.MillType_EndMill, 10);

}

else if (Unit == MeasureUnit.Imperial && outerDia > 0.6)

{

var endMillCounterboreOp = work.AddSubOperation(SubOperationType.Roughing);

endMillCounterboreOp.Tool = FindRotaryTool(ToolType.MillType_EndMill, 0.4);

}

else

{

//If the counterbore outerdia is less than 16mm or 0.6inch , i use a counterbore tool

var counterBoreOp = work.AddSubOperation(SubOperationType.Counterbore);

}

}

/// <summary>

/// This strategy is called to create a SIMPLE DRILLED holes

/// machining from recognized geometries.

/// </summary>

public void SimpleDrillStrategy()

{

var geometries = GetSelectedGeometries();

//From geometry recognizer function, i get all circles grouped by diameter.

//For every different diameter i create a different machining work

foreach (var groupedByDiameter in geometries)

{

// I get the first circle of the group to obtain the diameter value.

var firstCircle = groupedByDiameter.FirstOrDefault() as Circle;

if (firstCircle == null) continue;

var diameterValue = firstCircle.Radius * 2;

var work = AddMachineWork(WorkType.Mill_Drilling);

LinkGeometryToWork(work, groupedByDiameter);

work.MillingParams.DrillHoleDiameter = diameterValue;

work.MillingParams.DepthDrill = diameterValue * 5;

var centerDrillOp = work.AddSubOperation(SubOperationType.CenterDrilling);

var drillOp = work.AddSubOperation(SubOperationType.Drilling);

drillOp.Tool = FindRotaryTool(ToolType.DrillType_Drill, diameterValue);

}

}

Once the script is launched , this will be the project status, 15 operations are created automatically.

Note :

The effective holes depths must be adjusted manually , since there is no way to extract this information from a 2D drawing.